Dosing Pumps

Leading Manufacturers, Exporters, Wholesaler, Retailer, Distributor of Chemical Injection Skid Dosing System, Electronic Dosing Pumps, Hydraulic Diaphragm Type Metering Pumps, Mechanical Diaphragm Dosing Pump, Plunger Type Dosing Pumps, Skid Mounted Dosing System and Triplex High Pressure Plunger Pumps from Vadodara.

| Business Type | Exporter, Supplier |

| Country of Origin | India |

| Type | Chemical Dosing Skid |

| Feature | Good Strength, Longer Functional Life |

| Application | Pressure Updown |

| Power Source | Electric |

| Tank Capacity | Can Vary from Small Portable Tanks to Larger Storage Vessels. |

| Pressure | Low to 3500 Bar. |

| moc | Stainless Steel (304, 316, or Duplex) or Hastalloy or Inconel. |

-

CHEMICAL INJECTION SKID DOSING SYSTEM

WORKING PRINCIPLE:A Skid Mounted Chemical Dosing System is an integrated solution designed for precise chemical injection in various industrial applications. This chemical dosing system is typically pre-assembled on a skid, making it easy to install and maintain. The chemical injection skid includes pumps, tanks, and control systems, ensuring accurate chemical dosing and reliable performance. These systems, also referred to as chemical skid injection, are highly customizable to meet the specific needs of the cooling water system and other applications requiring precise chemical handling.

FEATURES: High precision dosing with metering pumps. Easy maintenance and servicing. Automated control system for easy operations and economical.

OVERVIEW: One Preparation and One Dosing Tank., Agitators, Single Dosing Pump or two (1W + 1S) Dosing Pumps, Instrumentation like Pressure Transmitter and Level Transmitter, Control Panel.

APPLICATIONS: The dosing system is commonly used for injecting chemicals into cooling water systems, water treatment plants, and other process industries.

OPTIONS:Solution preparation and/or storage tanks, which can be single or compartmented, made from materials like MS, SS, FRP, or HDPE, with optional rubber or FRP lining. Components such as chemical dosing pumps, gear/screw pumps, heat exchangers, stirrers (agitators), valves, fittings, and piping. Control panels and annunciators. Manufacturing is conducted strictly according to a Quality Assurance Plan aligned with the contract specifications.

LUBE OIL SKIDS

OVERVIEW: All critical components are lubricated regardless of location or ease of access. Measured amount of lubrication ensures no wastage of lubricant. Safety-No climbing around machinery. Lower energy consumption due to less friction. Engine parts are lubricated under pressure feed.

OIL HEATING AND PUMPING SYSTEMS

OVERVIEW: Compact unit as all components are mounted on a common skid. Predetermined constant temperature and pressure ensures efficient combustion. Unit is designed to supply heavy fuel oil like furnace oil. Comprised of electric heater, motorized rotary gear oil pump, pressure regulators etc.

GAS METERING SKID.

OVERVIEW: Natural Gas conditioning through scrubber-knock out drum/ filter separator/ Cartridge filter. Pressure regulation through direct acting/ pilot operated globe or axial regulators. Gas preheating for high flow/ high pressure drop application. Remote set point monitoring. Gas Odorizing.

FUEL HANDLING SYSTEMS

OVERVIEW: One Preparation and One Storage Tank. API 676- double or three Screw Pumps. Single Pump or two (1W + 1S) Pumps. Flameproof submersible pumps. Control Panel.

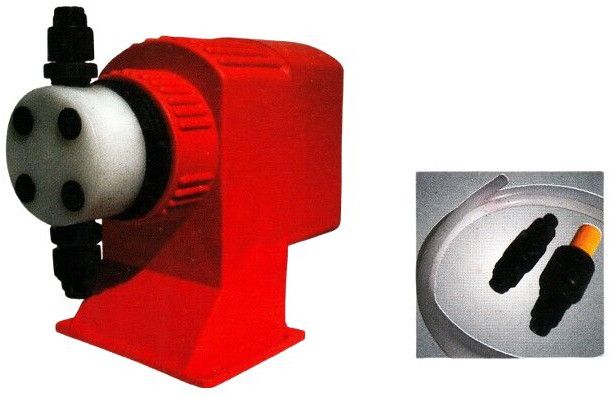

| Business Type | Exporter, Supplier |

| Pressure | Up To 10 KG/CM2,Up To 10 KG/CM2 |

| Capacity | 0–50LPH |

| MOC | PP, PTFE, AISI 316 |

| Power Source | Electric |

WORKING PRINCIPLE: Electronic dosing pumps use a complex electronic control system to precisely add a specific amount of liquid to a process. These are advanced chemical dosing pumps designed for precise and automated chemical injection. These pumps utilize electromagnetic technology to deliver accurate dosing, making them ideal for applications such as chlorine dosing in water treatment plants. As a type of digital metering pump, they offer high precision and control over dosing rates. Electronic dosing pumps are commonly manufactured for industries requiring exact chemical measurements. They are also known for their efficiency and reliability.

FEATURES: Electronically operated Mechanically Actuated Diaphragm. Solenoid Drive with minimum moving parts. Compact Size, Light Weight, More robust structure. Double Adjustment (Stroke Length and Frequency) is available.

APPLICATIONS: Small quantity Chemical Dosing, RO Plant, Water Treatment, Agriculture, Etc.

OPTIONS: Multiple Head with identical or different outputs for each head using single drive. Jacketed Head for Heating or Cooling the liquid been pumped. Automatic flow variation by receiving 4-20 mA signal from the process. The Design and Performance of the Pumps Conforms to API 675.

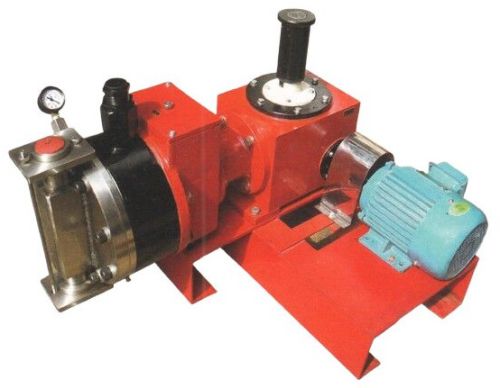

| Business Type | Exporter, Supplier |

| Country of Origin | India |

| Type | Hydraulic Diaphragm Pumps |

| Power | Electric |

| Pressure | Up To 100 KG/CM2 |

| Capacity | 0 - 7000 LPH |

| Accuracy at repeatability | + 3 % |

-

HYDRAULIC DIAPHRAGM TYPE DOSING / METERING PUMPS

(Single Diaphragm & Double Diaphragm / Sandwich Diaphragm)

WORKING PRINCIPLE:A hydraulic dosing pump, or metering pump, precisely moves a measured amount of fluid from a reservoir to a process by using a reciprocating motion (piston or plunger) driven by a motor or actuator, ensuring accurate dosing in applications like water treatment and chemical processes. Atype of chemical dosing pump widely used in industrial applications, particularly for water treatment plants. This diaphragm pump operates by using hydraulic fluid to actuate the diaphragm, allowing for precise, leak-free dosing of chemicals. As a diaphragm metering pump, it ensures accurate control of fluid flow and can handle corrosive or hazardous chemicals with ease. Designed for reliability, the chemical dosing diaphragm pump is perfect for water treatment processes where precise chemical dosing is critical. Its hydraulic actuation allows it to function effectively even in high-pressure environments.

FEATURES: Flow Rate is linear to Stroke Length variation. Diaphragm is always balanced between the Pressure Exerted by the Hydraulic Oil and the Liquid to be dosed. Longer Diaphragm Life. Inbuilt Pressure Relief Valve. Double Diaphragm/Sandwich Diaphragm with Rupture Indication Arrangement (RIA) is an additional facility available with these Pumps. Auto Dosing is also offered.

APPLICATIONS:100% League free Chemical Dosing, Solvents, Oils, Aggressive Liquids, PAC, Paint, Slurries, Hazardous and Toxic Chemicals, Corrosive liquids & Acids, Etc.

OPTIONS: Multiple Head with identical or different outputs for each head using single drive. Jacketed Head for Heating or Cooling the liquid been pumped. Automatic flow variation by receiving 4-20 mA signal from the process. The Design and Performance of the Pumps Conforms to API 675

| Business Type | Exporter, Supplier |

| Type | Dosing Pumps |

| Country of Origin | India |

| Capacity | 0 - 1200 LPH |

| Pressure | Up to 10 KG/CM2 |

| MOC | SS304, SS304L, SS316, SS316L, Hastalloy B, Hastalloy C, PP, PTFE. Diaphragm in PTFE |

WORKING PRINCIPLE: A Mechanically Actuated Diaphragm Dosing Pump is a reliable and precise chemical dosing pump used in

various industries, especially in water treatment plants. This diaphragm pump operates through a mechanical linkage, providing

accurate dosing without the risk of leaks. As a diaphragm metering pump, it is ideal for handling chemicals such as chlorine in

water purification systems. The chemical dosing diaphragm pump is engineered for consistent performance, making it a top

choice for chlorine dosing and other chemical injection processes. Often used as a motorized dosing pump, it ensures efficient,

automatic control of dosing rates in high-demand applications.

FEATURES: Leak-proof, glandless design ensures complete containment, mechanically operated diaphragm, Flow rate varies

linearly with stroke length adjustments, Steady state accuracy and repeatability within ±5%.

APPLICATIONS: 100% League free Chemical Dosing, chemicals like chlorine, coagulants, and flocculants in water, Pharmaceuticals,

fertilizers, bleaching agents, engine fluids Etc.

OPTIONS: Multiple heads with identical or varied outputs, all driven by a single motor. Automatic flow adjustment via variable

frequency drive (VFD).

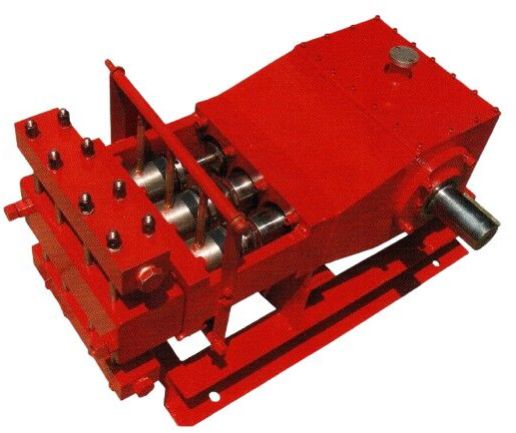

| Business Type | Exporter, Supplier |

| Speed | As Per Pump Model |

| Country of Origin | India |

| Type | Dosing Pumps |

| Application | Water Supply, Poly Electrolytes,Caustic,Lime,Shop,Resins,Molten Sulphur,Acids,Boiler Chemicals,Gel Etc. |

| Pressure | Up To 400 KG/CM2 |

| MOC | AISI 304, AISI 316, Hastalloy B, Hastalloy C, Etc. |

| Capacity | 0 - 10,000 LPH |

WORKING PRINCIPLE:A plunger dosing pump, also known as a plunger metering pump, works by using the reciprocating (back and forth) motion of a plunger to draw in and expel a precise volume of liquid through valves, ensuring accurate dosing.As a chemical pump, it uses a plunger mechanism to deliver accurate volumes of fluids, making it ideal for high-pressure environments. These pumps are commonly used as chemical dosing pumps in industries such as water treatment, oil and gas, and chemical processing. The motorized dosing pump option allows for automated control, ensuring reliable and consistent flow rates. Known for their durability and ability to handle corrosive chemicals, plunger dosing pumps are essential in precise fluid handling systems.

FEATURES: Precise Metering Devices. Flow Rate Adjustment From 0 - 100%. Metering Accuracy is almost Independent of Back Pressure. Multiple Head Pump with Common Drive is available for mixing two or more liquids in a desired ratio. GMP Models available for Food & Pharma applications. Liquid Head & NRV Cooling or Heating Jacket is Possible. Plunger is hard chrome plated. Flow rate is linear to stroke length variations. External arrangement for flushing the gland packing to increase its life is also possible.

APPLICATIONS: Polyelectrolytes, Caustic, Lime, Soap, Resins, Molten Sulphur, Acids, Boiler Chemicals, Cooling Water Chemicals, Gel, Cream, Toothpaste, Butter, Chocolate, Etc.

OPTIONS: Multiple Head with identical or different outputs for each head using single drive. Jacketed Head for Heating or Cooling the liquid been pumped. Automatic flow variation by receiving 4-20 mA signal from the process.

The Design and Performance of the Pumps Conforms to API 675

| Business Type | Exporter, Supplier |

| Power Source | Electric |

| MOC | MS, SS, HDPE, PP, Rubber / FRP Lined, Etc. |

| Pressure | Up to 400 kg/cm2 or 500 bar. |

| Capacity | Can range from 0.01 to 30,000 L/h |

WORKING PRINCIPLE: A skid-mounted dosing pump system precisely meters and injects chemicals into a process stream, ensuring accurate dosage and safety, by drawing chemicals from a tank, controlling flow with a pump and flow meter, and delivering them to the process via a skid-mounted unit.

FEATURES: Typical Dosing Systems incorporates Chemical Dosing pumps one or more. Solution Preparation Tank of Single or Multi Compartmented. Stirrer (Agitator), Strainers, Valves, Fittings, Interconnecting Piping, Pressure Gauges, Level Gauges, Level Switches, NRV, PRV Controllers, Sensors, etc. are offered as per the requirement. Scada Control Panel & Atomization can be provided as per the requirement.

APPLICATIONS:LP & HP Dosing Systems for Boiler Feed Water Treatment, Corrosion Inhibitor Dosing System, Polyelectrolyte Solution preparation & Dosing System, Hypochlorite Dosing System, Cooling Tower Chemicals Dosing System, Water Treatment Chemicals Dosing System, Odorizing & Deodorizing Chemicals Dosing Systems, CW Systems, Lube Oil Systems, PPD Dosing System, Wax Inhibitor Dosing System, Lime Dosing System, Chlorine Dosing System, Alum Dosing Systems, Antiscalent Dosing Systems, Chlorine Dosing Systems, Chemical/Methanol injection packages, Oil pipeline injection package, Water injection packages. Etc. Also offered Customized Systems.

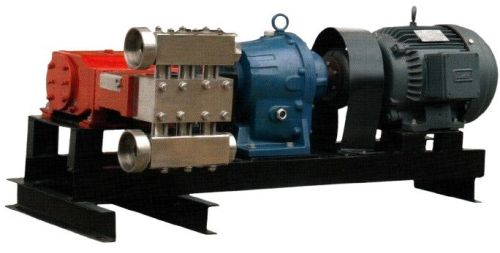

| Business Type | Exporter, Supplier |

| Application | High Pressure Jetting,Cleaning,Descaling,R.O.,Boiler Feed,Etc. |

| Pressure | Up To 800 KG/CM2 |

| Capacity | Up to 25M3/HR |

| MOC | SS316, SS304, CS, Brass, Etc. |

| ower Source | Electric |

HIGH PRESSURE TRIPLEX PLUNGER PUMPS

WORKING PRINCIPLE: A high-pressure triplex dosing pump, a type of positive displacement pump, works by using three plungers to create a continuous flow of liquid at high pressure, driven by a crankshaft and connecting rods, with each plunger having its own inlet and outlet check valves.

FEATURES: Simple and Sturdy Construction. Volumetric efficiency as high as 95%.

OVERVIEW: Performance conforms to API 674.High performance non return valves on suction & delivery side. Highly convenient for maintenance. Plunger is hard chrome plated. Flow rate is fixed capacity. The liquid end part can be equipped with cooling, heating or flushing systems depending upon the application.