Centrifugal Pumps

Leading Manufacturers, Exporters, Wholesaler, Retailer, Distributor of Fire Fighting Pumps, Centrifugal Water Chemical Process Pumps, FRP Mouled Centrifugal Chemical Process Pumps, Horizontal Multistage Pumps, Non Clog Self Priming Pumps and Sanatery Centrifugal Pumps from Vadodara.

| Business Type | Exporter, Supplier |

| Type | Fire Fighting Pump |

| Country of Origin | India |

| Motor / Engine Power | From 3 HP to 700 HP |

| Capacity | Upto 700 M3 / Hr |

| Head | Upto 240 M |

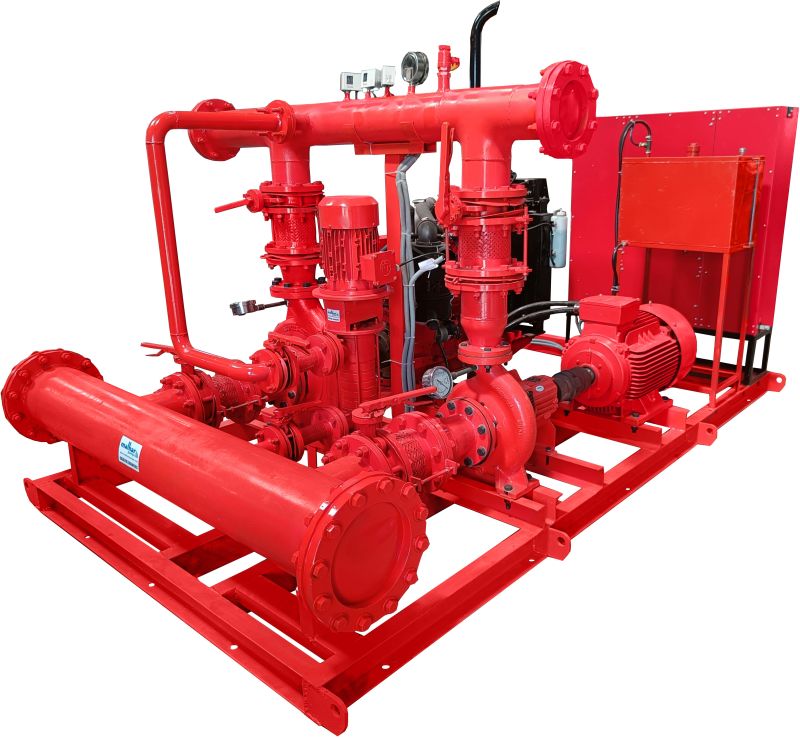

FIRE FIGHTING PUMPS

Features : Fire pumps may be powered by an electric motor or a diesel engine, or occasionally a steam turbine. Fire pumps are needed when the local municipal water cannot provide sufficient pressure to meet the hydraulic design requirements. Fire pumps are also needed if the fire protection water supply is provided from a ground level water storage tank. These are Single stage / Multistage and Multi outlet pumps. Types of pumps used for fire service includes: horizontal split case, vertical split case, vertical inline, vertical turbine, and end suction. It has a control panel that contains all controls, including ON / OFF switches, Manuel- Auto switches, Pressure Switch Connections & Connection for Auto start of engine.

Jockey Pump : These are normally High-Pressure multistage pumps, are maintaining Desired pressure in system. (normally 7 kg to 11 kg)

Motor Driven Pumps : On opening the main valve, this pump will start and throw forcefully water on fire. (normally pressure 7 kg to 11 kg)

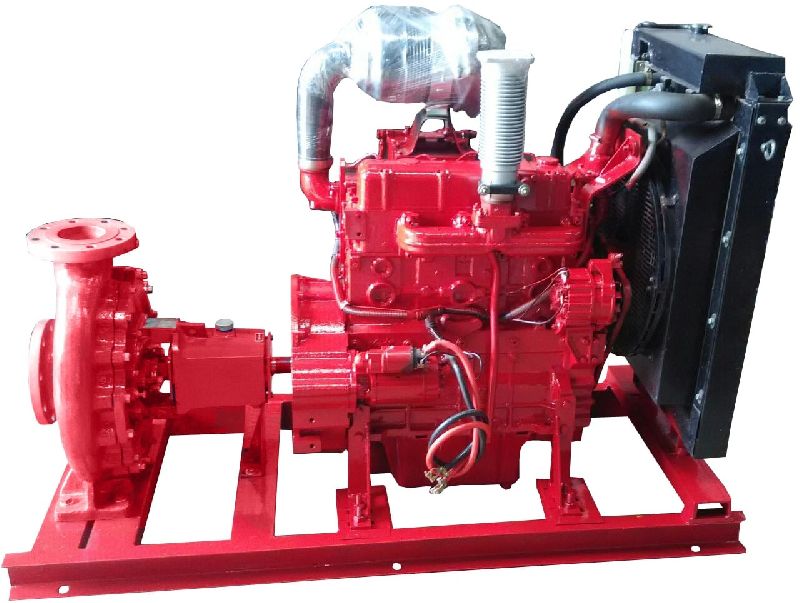

Engine Driven Pumps : During fire, power supply or cable fault happen so motor driven pump unable to work in such case engine driven pump will start and serve the purpose. (normally pressure 7 kg to 11 kg)

Applications : Petroleum, Oil & Gas, Refineries, various Offshore Installations, Residential & Commercial complexes, High rise buildings, Airports & Ports, Power Stations & Transformer Stations, Petroleum & Petrochemical complexes, Warehouses, Manufacturing and Chemical Industry.

| Business Type | Exporter, Supplier |

| Type | Chemical Process Pump |

| Country of Origin | India |

| Capacity | Up to 900 M3 / HR |

| Head | Up to 180 Mtrs |

| Temperature | Up to 350 ºC |

| M.O.C | Graded Cast Iron, NICI, CF8, CF8M, SS316L, CD4MCUN, Etc. |

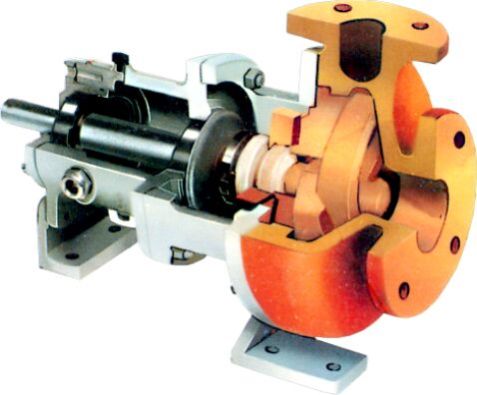

WORKING PRINCIPLE:A centrifugal pump's working principle is based on the concept of converting mechanical energy into hydraulic energy. It applies centrifugal force on a fluid through rotation to generate the desired pressure and flow. It imparts velocity to a liquid, which is subsequently converted into a continuous flow.

FEATURES: End Suction Back Pull Out Design with Close, Semi Open and Open Impeller. Steady Flow, High Efficiency and Sturdy Construction. Low NPSH, Low Noise and Maintenance Free. Environmental Friendly & Shaft Deflection Below 0.05 mm. Pumps offered with Gland Packing and Mechanical Seals. Casing Cover Cooling or Heating Jacket is Possible. Impellers are balanced Dynamically. Simple External Axial Adjustment for Impeller Wear and Tear in some Designs. Design in accordance with 24255 / EN 733, 24256 / ISO 2558, ANSI B 73.1. Deep Groove Ball Bearings / Double Row Angular Contact Ball Bearings / Cylindrical Roller Bearings are provided as per the Requirement & Design. Well point Dewatering Pumps with Engine Drive and Trailer are also offered for Remote Areas.

APPLICATIONS: Handling Clean or Turbid water, Condensate Water, Fire Fighting, Air Conditioning, Irrigation, Sprinkler System, Cooling Towers, Booster Services, Sea Water, Mines, Chemicals and Petrochemicals, Dyes and Intermediates, Acids, Hydrocarbons, Distilleries, Liquors, Thermic Fluid, Hot Oils, Brine, Alkaline Solutions, Solvents, Corrosive Liquids and Slurries, Pulp & Paper Stock, Etc.

| Business Type | Exporter, Supplier |

| Type | Chemical Process Pump |

| Country of Origin | India |

| Power Source | Electric |

-

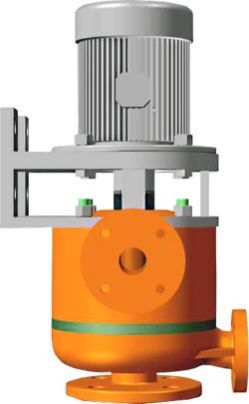

FRP MOULED CENTRIFUGAL CHEMICAL PROCESS PUMPS WITH VINYLESTER RESIN

WORKING PRINCIPLE:FRP molded centrifugal chemical process pumps with vinyl ester resin use a rotating impeller to increase fluid pressure, which is then used to move the liquid through the pump's casing and discharge pipe, leveraging the centrifugal force generated by the spinning impeller.

FEATURES: End Suction Back Pull Out Design. High efficiency due to unique moulding process, longer life and high temperature withstand compare to PP Pumps.Substantial cost savings. Light weight, reliable and long lasting. Signal Volute Casing with contoured discharge for high efficiency against straight line discharge in other non-metallic pumps. Excellent corrosion resistance. No cracks or damage of wetted components due to free chlorine. A momentary dry running cannot melt the Casing and Impeller. Hence, there is no jamming of the pumps. Substantial cost savings.

Capacity : Up to 180 M3/HR

Head : Up to 80 Mtrs

APPLICATIONS: Acids like Concentrated Hydrochloric Acid (HCL), Dilute Sulphuric Acid (H2SO4), Pickling / Electroplating Solutions, Sea Water/Brine, Water and Waste water treatment applications, high Corrosive, contaminated and aggressive liquids, Caustic Soda, Scrubbing, Etc.

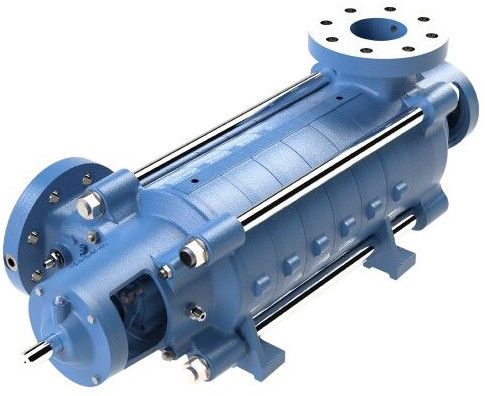

| Business Type | Exporter, Supplier |

| Type | Horizontal Multistage Pump |

| Structure | Horizontal |

| Country of Origin | India |

| Pump Capacity | Up to 125 M3/Hr |

| System Capacity | Up to 840 M3/Hr |

| Head | Up to 254 MWC |

| Temperature | 20 °C to 140 °C |

WORKING PRINCIPLE: Horizontal Centrifugal Chemical Process Pumps have a single-stage, horizontal end suction design with semi-open impellers. The foot-mounted volute casing allows easy maintenance by back pull-out design, allowing the driving assembly to be removed without disrupting pipe connections. Multistage centrifugal pumps, whether vertical or horizontal, work by using multiple impellers in series to increase fluid pressure through sequential stages, where each impeller adds kinetic energy, which is then converted to pressure energy.

FEATURES: Single Suction, Radially Split, Horizontal Shaft Design. Impellers are fully Shrouded. Each Stage is provided with a Guide Vane to Guide the Discharge from one Impeller to the Suction of the other Impeller. Hydraulic section and pump housing completely made from stainless steel. Solid and robust pump housing. Conforms to the quality labels: CE ATEXWRas ACS. Most Energy Efficient Pumps. Silent, stable and vibration free. Special design of motor cooling fin and impeller cover. Optimised flow through. Reduction of servicing time and process halt. Hydro-Unit Systems also offered.

APPLICATIONS: Fire Fighting, Sprinkler Irrigation, Light Chemicals, Boiler Feed, Booster Plants, RO, WTP, light aggressive fluids, Residential construction, General Water Supply, HVAC Hot & cold water circulations, Fire-fighting, Light industrial applications, Transportation & Pressure Boosting of (drinking) water, Air conditioning, Boiler Feed, Mine Dewatering, RO. WTP, Etc.

| Business Type | Exporter, Supplier |

| Capacity | 275 M3 / HR |

| Head | Up to 36 Mtrs |

| Solid Handling Size | Up to 40MM |

| MOC | Cast Iron, Stainless Steel, Etc. |

WORKING PRINCIPLE:Self-priming non-clog pumps work by recirculating fluid within the pump casing to create a vacuum that evacuates air from the suction line, allowing the pump to draw liquid and solids, even when the suction line is initially empty.

FEATURES: Horizontal, End Suction Non-Clogging Design with Open Impeller. Available in Bare, Coupled, Monoblock Design. Belt driven & Engine driven versions also offered.

APPLICATIONS: Handling Polluted liquids, Underground Tank Liquids, Chemicals, Sewage, Muddy water or Fresh water, Tiles & Marble Slurries, Effluents, Etc. Dewatering Basements, Trenches, Swimming Pools, Sump Drainage, Construction sites. Etc. Any Application where Priming is to be avoided.

| Business Type | Exporter, Supplier |

| Country of Origin | India |

| Capacity | 04 Lpm to 2000 Lpm |

| Head | 04 Meters to 80 Meters |

| MOC | SS 304, SS 316, SS 316L |

| Motor HP | 0.25 HP TO 30 HP |

WORKING PRINCIPLE:A sanitary centrifugal pump, used in food and beverage processing, works by converting mechanical energy into kinetic energy, which then drives the fluid outward through a rotating impeller, creating a pressure difference that moves the fluid.

FEATURES: Minimum Working / Rotating parts made from Rolled Stainless Steel. Super Finish surface also ensure No Ingress or Emission of Germs or Impurities during Pumping or Idling which is basic requirement of Sterile / Hygienic application. Monoblock or Bare Pump with STD / Flame Proof Motor versions. Self-priming design with priming chamber version is also offered. Various type of End Connections

As all pumps are made from rolled stainless steel, mechanical properties are far superior then cast material.

• Pore free, non-pitting and non-adhering smoother surface, so less friction losses, and less service corrosion.

• Super finish surface also ensure no ingress or emission of germs or impurities during pumping or idling which is basic requirement of sterile hygienic application.

• Designed for CIP (clean in place) or manual cleaning

• Pumps are highly energy efficient and requires less NPSH to function without cavitation’s

• Pump can handle liquids having viscosities up to 1500 centipoises

• The pumps can work under a vacuum of 720 mm of Hg, suitable for vacuum evaporators.

• The best elastomers are used in the pumps to provide optimum resistance for high temperatures and chemicals.

• Pumps are available with open/semi open impellers.

• Minimum working / rotating parts

• Safe and quite operation levels.

• Gentle product handling with lower maintenance and down line cost.

• Dynamically combinations of seal faces as per customer’s requirement (single seal / double seal, seal external cooling)

• Suitable for standard motor or flange type or foot cum flange type motor or engine.

• Monobloc or bare pumps or with trolley.

• Also with flame proof Motors.

• Various types of connection like – triclove joints SMS, flanges or threaded nipple/coupling.

• Pumps with adjustable legs, available on request.

APPLICATIONS: Milk, Cream, Fruit Juice, Alcoholic Drinks, Soft Drinks, Vitamin Solutions, Sugar Syrup, Vegetable Oil, Mineral Oil, Acids, Fine Chemicals, Alkaline Solutions, RO Water, DM Water, Etc.