| Business Type | Exporter, Supplier |

| Temperature | Up To 200 °C |

| Pressure | Up To 14 Bar |

| Capacity | Up to 800 LPM |

| Click to view more | |

Product Details

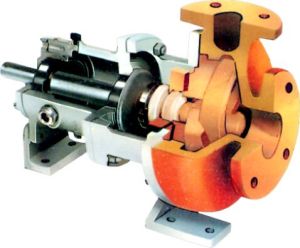

ORKING PRINCIPLE: DIG series employs proven Internal Gearing (Gear within Gear) principle for pumping. The main gear is keyed to the drive shaft, and rotates concentric in the pump casing. Idler is located on an eccentric pin on the front cover to rotate freely and meshes with main gear when assembled. A crescent shaped partition precision machined on the front cover maintains a small, but positive clearance to achieve perfect scaling between parts. As the gears come out of mesh, a partial vacuum is created, forcing the fluid to rush into the pump casing and fill in the voids between the teeth. Both gears rotating in the same direction of rotation gently transfer the fluid to the delivery port. The resulting action is a smooth-steady flow; low in pulsation, noise and vibration. Single shaft design well supported on outboard bearing (except for one inside sleeve bearing) enables to pump products even with poor lubricating value unlike in the external gear pumps. External bearing construction offers easy access the pump components i.e., rotor set and even pump casing simply by removing the front cover without disturbing drive parts, bearings etc., and in place. Block pump mounted integrally on hollow shaft gearbox automatically reduces the speed (in several ratios) and enables even the pump rotor to be pulled out without disturbing the drive! It is easily possible to jacket front and rear covers for products heating - thus making the design unique and versatile - ideally suited for process pumping.

FEATURES: Single shaft design & well supported on outboard bearing (except for one inside sleeve bearing) enables to pump products even with poor lubricating value unlike in the external gear pumps. Excellent Self priming, Insensitive to viscosities, Smooth quite flow & Low noise. Bracket / Gear box mounting allows free Expansion / Contraction - Alignment not affected. Easy Maintenance. Slow speeds ensure better pumping & longer life. Heating / Cooling Jacket possible. Choice of Mechanical Seal / Stuffing box is available for shaft sealing. Available with Inbuilt Relief Valve.

APPLICATIONS: Loading & Unloading of Tankers, Transfer of Liquids like, Batter, Bitumen, Butter, Caramel, Chocolate, Cheese, Fats, Fruit Drinks & Puree, Fudge, Gelatin, Glucose, Gum, Honey, Jam, Ketchup, Lotions, Molasses, Oils, Printing Ink, Chilly Paste, Shampoo, Starch, Syrups, Tar, Tooth Paste, Yeast Slurry, Baby Foods, Fruit Concentrates, Cookie Dough, Putty, JelliesEtc.