| Business Type | Exporter, Supplier |

| Pressure | Up to 24 KG/CM2 |

| Capacity | Up to 200 M3/HR |

| Temperature | From Cryogenic to 120 °C |

| Click to view more | |

Product Details

-

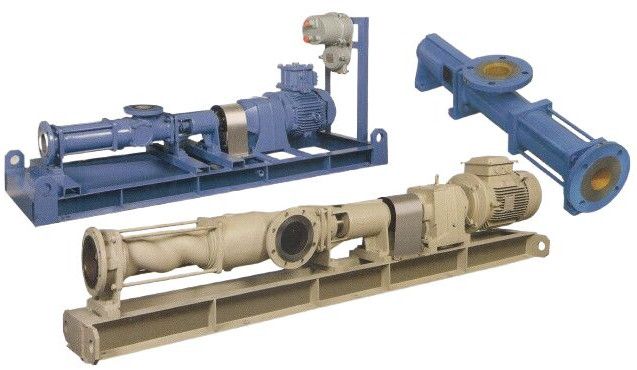

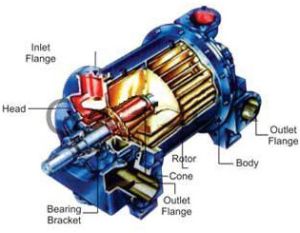

PROGRESSIVE CAVITY PUMPS / SINGLE SCREW PUMPS

WORKING PRINCIPLE: The pumping elements are rotor and stator. The single helical rotor rolls eccentrically in a double threaded helix stator of twice the pitch length. A series of sealed cavities 180° apart are created that appear to progress from suction to discharge during one rotation of rotor. The opposing cavities fill and empty simultaneously resulting in a pulsation less flow. The fluid travels axially with relatively low velocity and minimal agitation. The stator is made of a resilient elastomeric material and bonded to the stator tube. The important feature of the pumping principle is the ability to handle slurries and solid particles. The elastomeric stator also permits passage of solid particles due to elastomeric deformation. Direct drive with moto Through gear box, V-belt pulleys, Variable speed drives, Special drives such as hydraulic, with I.C. engines.

FEATURES: Simplicity of Design and Easy for Maintenanceof the pump enables complete maintenance of the pump without removing the suction and discharge pipelines. Sturdy drive design provides strength for rigorous continuous operation. Unique joint design is very simple and maintenance free joint, does not require replacement due to wear and tear, common in other joint designs. Can Pump All Type of Media, Low & High Viscosities, Abrasive Slurries, Solids in Suspension up to 60%. Liquid from Vacuum & mediums containing Gas can also be pumped. Vulcanized Stator simply to be changed. The pumping elements are Rotor and Stator, Stators are available in a wide range of elastomeric. Sturdy drive design provides strength for rigorous continuous operation. Close coupled models with built-on speed reducers offer compact pumping unit. Hopper type and Vertical Mounting Pumps are also offered.

APPLICATIONS:Loading and Unloading of Tankers, Polymer Feed, Dewatering Sludge Transfer, Kiln Charging Drainage, Transfer of Liquids like Molasses, Pastes, Slurries, Fruit Pulp, Fruit Juice, Cream, Glucose, Ink, Paint, Soap, Honey, Resins, Filter Press Feeding, Effluent Sludge, Oil Sludge, Raw Fats, Fish Residues, Baby Food, Beer, Fruit Pulp, Beet Sludge, Biscuit Dough, Mustard, Tomato Paste, Crude Oil, Dye, Cellulose, Sewage, Various kind of Slurries,Effluent with & without solids, Milk of Lime, Alcoholic Beverages, Apple Puree, Baby Food, Beer, Beet Sludge, Biscuit Dough, Citrus Fruit Masher, Acids, Adhesives, Caustic Soda, Cellulose, Cement Slurry, Glue, Lacquers, Hair Oil, Hand Washing, Cream, Paints, Shampoos, Waxes, Lard, Meat Extract, Milk, Mustard, Tomato Paste, Vegetable Oil, Wine, Yeast, Cream Cheese, Edible Oil, Eggs, Raw Fats, Fish Residues, Fruit & Berry Masher, Honey, Ice Cream, Protective Chemicals Etc.