| Business Type | Exporter, Supplier |

| Material | MS |

| Finishing | Polished |

| Power Source | Pneumatic |

| Click to view more | |

Product Details

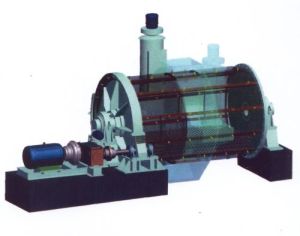

WORKING PRINCIPLE:Drying, roasting, heat treatment and cooing is achieved by passing the material being processed through a rotating horizontally inclined cylindrical drum. The stream of hot gas / air for drying and cold air for cooling, also, passes through the drum. As the drum rotates, the internals, Pusher Flights and “Lifters”, fitted into the drum tumble, slide, lift and shower and cascades the material into the air steam. In co- current dryers, the hot gas/air stream flows in the same direction as that of the product being dried, and in counter current model the drying gas / air stream travels against the flow of the product being dried. ln these dryers the product is directly exposed to i.e. in contact of the stream hot gas / air produced by the heat source.

FEATURES:Rotary Drum Dryers are capable of handling large tonnage throughput and are built to with stand rough, rigorous, continuous operation with minimal down time. Rotary Drum Dryer offers a simple solution for continuous drying, cooling, roasting and heat treatment of particulate/bulk solids.

APPLICATIONS: Agricultural Grains & By-Products, Biosolids, Municipal Waste, Paper Sludge, Steel Mill Waste Sludge, Ceramics, Aggregates, Organic & Inorganic Chemicals, Iron Ore Concentrates, Mining Ores & Concentrates, Metal Chips & Shavings, Plastic Pellets.