| Business Type | Exporter, Supplier |

| Material | Mild Steel |

| Finishing | Polished |

| Shape | Rectangular |

| Click to view more | |

Product Details

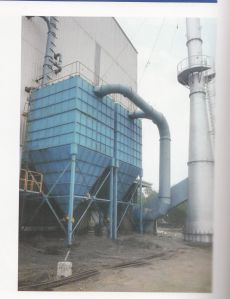

WORKING PRINCIPLE: Pulse Jet Hose Bag Type Filters / Pulse Jet Bag Filter are known as conventional filters. A Pulse Jet Envelope Type Bag Filter/Cassette Type Dust Collector works by filtering dust-laden air through bags, accumulating dust on the outer surface, and then using short bursts of compressed air (pulses) to dislodge the dust, which then falls into a collection hopper.

FEATURES: Basically used for applications where there is height constraint or front loading of filter elements are required. This design works very well for the critical powder handling, product recovery and for all other general purpose application. Downdraft Airflow Direction for Best Dust Separation At Inlet. Continuous Duty Operation. Lower Pressure Drop in Comparison with Hose Bag Type Bag Filters. Options for Discharge Devices. Reverse Air Cleaned Envelope Type Bag filters are also offered of Higher Capacities for Foundries and other applications.

Capacity : Modular Design Available up to 1,00,000 CMH.

MOC : Available in Mild Steel & Stainless Steel

APPLICATION: Pulse jet envelope (or cassette) type bag filters, are widely used for removing particulate matter from industrial exhaust gases and are effective in industries like cement, steel, power generation, and chemical processing.