| Business Type | Exporter, Supplier |

| Pressure | Up To 100 Bar |

| Capacity | Up to 3000 LPM |

| Viscosity | Up to 25000 cSt |

| Click to view more | |

Product Details

-

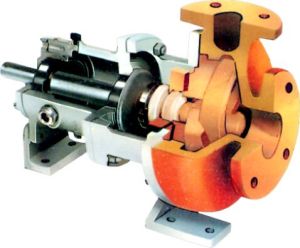

THREE SCREW PUMPS / TRIPLE SCREW PUMPS

WORKING PRINCIPLE: Three Screw pumps employ just three screw elements - one power screw and two idler screws running in the three precision bores in the housing or liner. The screws are so profiled that they form a liquid tight seal between the thread. As the screws rotate, pockets/ cavities are formed where liquid gets trapped and conveyed from one end of the infinite stroke. This results in smooth, pulsation free flow with extremely low noise and vibration levels, almost impossible to be achieved by any other design of positive displacement or other types. The power rotor does not drive the idlers as commonly believed. The hydraulic forces acting on screw flanks turn the idlers torquelessly thus reducing the friction. The idlers simply roll over the root diameter of idler dia. reduce the unit pressure, centralize the power rotor and absorb the radial loads. A balance piston integrally machined on power rotor takes care of axial thrusts. While in operation, the screws are in hydrodynamic balance on film lubrication and do not require any additional bearings. The one ball bearing often used is only for axial positioning of rotor and safer operation of mechanical seals. Small rotor dimensions enable the pump to be operated at high speeds directly coupled 3000 or 3600 RPM motors or other prime movers. Such unique design and features has demonstrated excellent reliability with pumps in operation continuously non-stop for decades together without replacement of any components or maintenance on clean fluids.

FEATURES: Employ just three profiled screw elements. One power screw and two idler screws running in the three precision bores in the housing or liner. Smooth, pulsation free flow with extremely low noise and vibration levels. High Efficiency, Reliability & Negligible maintenance. Self Priming, Axial flow - no churning, chewing or shearing & Insensitive to viscosities Available with Inbuilt Relief Valve. High speed capability, Insensitive to viscosities, High pressure capability, Axial flow - no churning, chewing or shearing, Excellent suction capability, Hydraulic balancing of forces eliminates need for any bearings.

APPLICATIONS: Fuel Oil LDO, FO, HSD, LSHS Burner Service, Booster Service, Circulation & Transfer for Thermal Power Plant, Industrial Package, Boilers, Furnaces, Kilns, Combustion systems, Centrifuge Feeding. Fuel transfer and booster service for Captive Diesel/ Gas Turbine Plants and Industrial Combustion Systems, Fuel Oil Circulations and Centrifuge Feeding. Tank farm tank to tank transfers. Hydraulic governing service, Low and medium pressure hydraulic applications & high pressure jacking oil service for rotor lifting for Turbines/ Compressors/ Alternators. Low and medium pressure hydraulic applications, high pressure jacking oil service for rotor lifting for Turbines/ Compressors/ Alternators. Pressure lubrication and cooling of bearings for Turbo Machinery, Gear Boxes, Bearing Lubrication of Coal Mills, ID/FD Fans, Diesel Engines, Steel Rolling Mills, Air pre-heater guide bearings, Compressors. Seal Oil Services for Hydrogen cooled Generators, Gas and Refrigeration Compressors, Hydrogen cooled Generators, Gas and Refrigeration Compressors, Etc.