Pneumatic Conveying Systems

| Business Type | Exporter, Supplier |

| Country of Origin | India |

- DENSE PHASE PNEUMATIC CONVEYING SYSTEMS

OVERVIEW: Conveying velocities are designed relatively lower & under 5 mtrs/sec. However, starting pressures sometimes exceed 3 to 4 Bar designed commensurate with the distances to be conveyed & system resistance. The pipe diameters are designed as per the throughput requirement & however, work out relatively smaller. The pneumatic conveying system for the dense phase is an effective method to move difficult, abrasive, and friable materials at a slow speed. It pushes material along an enclosed pipe, in a plug form, using small amounts of gas, at a low velocity but medium and high pressure. It has few wearing parts which contribute towards minimal maintenance. Also, the production costs benefit as there is low material degradation, especially when conveying fragile materials.

FEATURES:Closed loop system - thus eliminating dusting. Higher conveying distances are possible as compared to Mechanical transfer. Small sized vent filters due to low amount of airflow involved as compared to lean phase systems. Less breakdown incidences & single point Maintenance plus low wear & tear of the conveying parts. No need of any Dust Collection systems.

| Business Type | Exporter, Supplier |

| Driven Type | Penaumatic |

| Color | Blue |

| Automatic Grade | Fully Automatic |

| Application | Industrial |

| Voltage | 220V |

| Country of Origin | India |

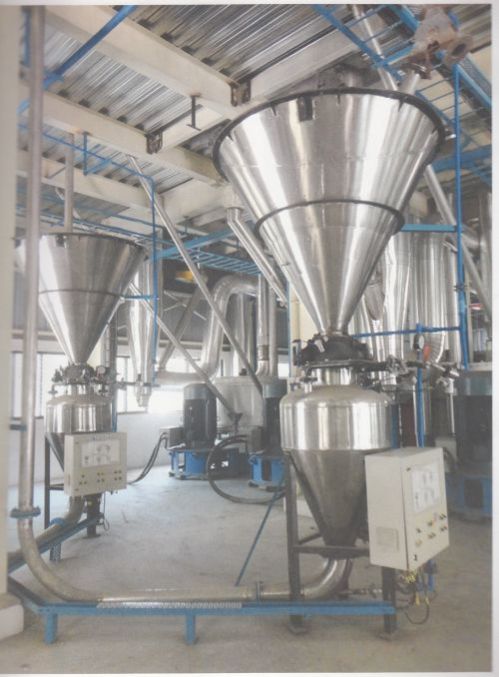

- PNEUMATIC CONVEYING SYSTEMS (DILUTE / LEAN PHASE)

OVERVIEW: Solid, Granular & powdered materials have been handled conventionally, by mechanical conveying equipments such as belt conveyors/screw conveyors/ bucket elevators/ goods lifts etc. In this system, the material is conveyed with the help of a Centrifugal Blower/Roots Blower/Regenerative Blower, for example, a powder conveying system employs both pressure and vacuum to transport materials as they were liquids vertically and horizontally to and from process devices. Here material is conveyed either by negative suction or by positive pressure of blower.

FEATURES: Suitable for complex plant layouts and for less fluidizable material.Higher conveying distances are possible as compared to Mechanical transfer.Less breakdown incidences & single point Maintenance.Single point utilities (Air, ElectricaIs) connection. No requirement of storage hopper for transfer. Suitable for long distances & multiple locations.

Capacity: Upto 40 TPH

APPLICATION: Used in industries like food processing, pharmaceuticals, chemicals, agriculture, Salt, Cement Industry, Power Handling System, Carbon Black Applications, Diatomaceous Earth, Foundry Minerals, etc.

-

PNEUMATIC CONVEYING SYSTEMS

WORKING PRINCIPLE: Pneumatic conveying systems move dry bulk materials (powders, granules) through enclosed pipelines using compressed air or gas, relying on pressure differential and airflow to transport the material.

FEATURES: Transfer Dust Free of Dry Solids, Powder, Granules, Pellets & Chips from Single / Multiple Points to very long distances & Multiple Locations. Depends upon Application and conveying solid, two types of systems are offered: (1) Dense Phase Systems (Conveying with the help of Compressed Air). (2) Dilute Phase / Lean Phase Systems (Conveying with the help of Blower Air) a) Vacuum Conveying (Negative Conveying) b) Pressure Conveying (Positive Conveying)