| Business Type | Exporter, Supplier |

| Type | Chemical Process Pump |

| Country of Origin | India |

| Power Source | Electric |

-

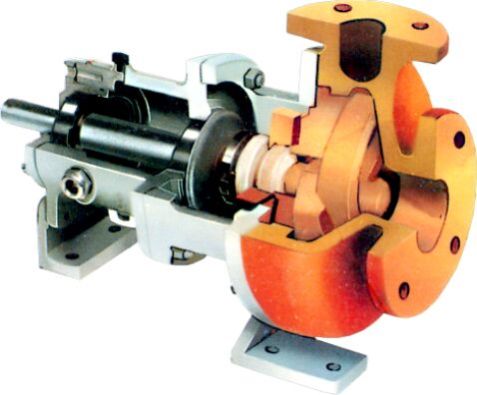

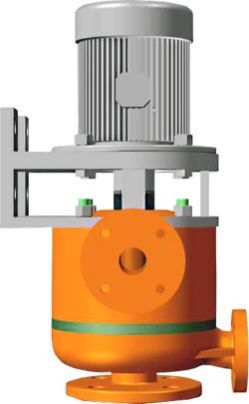

FRP MOULED CENTRIFUGAL CHEMICAL PROCESS PUMPS WITH VINYLESTER RESIN

WORKING PRINCIPLE:FRP molded centrifugal chemical process pumps with vinyl ester resin use a rotating impeller to increase fluid pressure, which is then used to move the liquid through the pump's casing and discharge pipe, leveraging the centrifugal force generated by the spinning impeller.

FEATURES: End Suction Back Pull Out Design. High efficiency due to unique moulding process, longer life and high temperature withstand compare to PP Pumps.Substantial cost savings. Light weight, reliable and long lasting. Signal Volute Casing with contoured discharge for high efficiency against straight line discharge in other non-metallic pumps. Excellent corrosion resistance. No cracks or damage of wetted components due to free chlorine. A momentary dry running cannot melt the Casing and Impeller. Hence, there is no jamming of the pumps. Substantial cost savings.

Capacity : Up to 180 M3/HR

Head : Up to 80 Mtrs

APPLICATIONS: Acids like Concentrated Hydrochloric Acid (HCL), Dilute Sulphuric Acid (H2SO4), Pickling / Electroplating Solutions, Sea Water/Brine, Water and Waste water treatment applications, high Corrosive, contaminated and aggressive liquids, Caustic Soda, Scrubbing, Etc.