| Business Type | Exporter, Supplier |

| Country of Origin | India |

| Type | Chemical Dosing Skid |

| Feature | Good Strength, Longer Functional Life |

| Click to view more | |

Product Details

-

CHEMICAL INJECTION SKID DOSING SYSTEM

WORKING PRINCIPLE:A Skid Mounted Chemical Dosing System is an integrated solution designed for precise chemical injection in various industrial applications. This chemical dosing system is typically pre-assembled on a skid, making it easy to install and maintain. The chemical injection skid includes pumps, tanks, and control systems, ensuring accurate chemical dosing and reliable performance. These systems, also referred to as chemical skid injection, are highly customizable to meet the specific needs of the cooling water system and other applications requiring precise chemical handling.

FEATURES: High precision dosing with metering pumps. Easy maintenance and servicing. Automated control system for easy operations and economical.

OVERVIEW: One Preparation and One Dosing Tank., Agitators, Single Dosing Pump or two (1W + 1S) Dosing Pumps, Instrumentation like Pressure Transmitter and Level Transmitter, Control Panel.

APPLICATIONS: The dosing system is commonly used for injecting chemicals into cooling water systems, water treatment plants, and other process industries.

OPTIONS:Solution preparation and/or storage tanks, which can be single or compartmented, made from materials like MS, SS, FRP, or HDPE, with optional rubber or FRP lining. Components such as chemical dosing pumps, gear/screw pumps, heat exchangers, stirrers (agitators), valves, fittings, and piping. Control panels and annunciators. Manufacturing is conducted strictly according to a Quality Assurance Plan aligned with the contract specifications.

LUBE OIL SKIDS

OVERVIEW: All critical components are lubricated regardless of location or ease of access. Measured amount of lubrication ensures no wastage of lubricant. Safety-No climbing around machinery. Lower energy consumption due to less friction. Engine parts are lubricated under pressure feed.

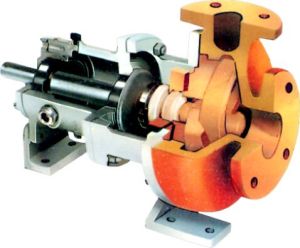

OIL HEATING AND PUMPING SYSTEMS

OVERVIEW: Compact unit as all components are mounted on a common skid. Predetermined constant temperature and pressure ensures efficient combustion. Unit is designed to supply heavy fuel oil like furnace oil. Comprised of electric heater, motorized rotary gear oil pump, pressure regulators etc.

GAS METERING SKID.

OVERVIEW: Natural Gas conditioning through scrubber-knock out drum/ filter separator/ Cartridge filter. Pressure regulation through direct acting/ pilot operated globe or axial regulators. Gas preheating for high flow/ high pressure drop application. Remote set point monitoring. Gas Odorizing.

FUEL HANDLING SYSTEMS

OVERVIEW: One Preparation and One Storage Tank. API 676- double or three Screw Pumps. Single Pump or two (1W + 1S) Pumps. Flameproof submersible pumps. Control Panel.